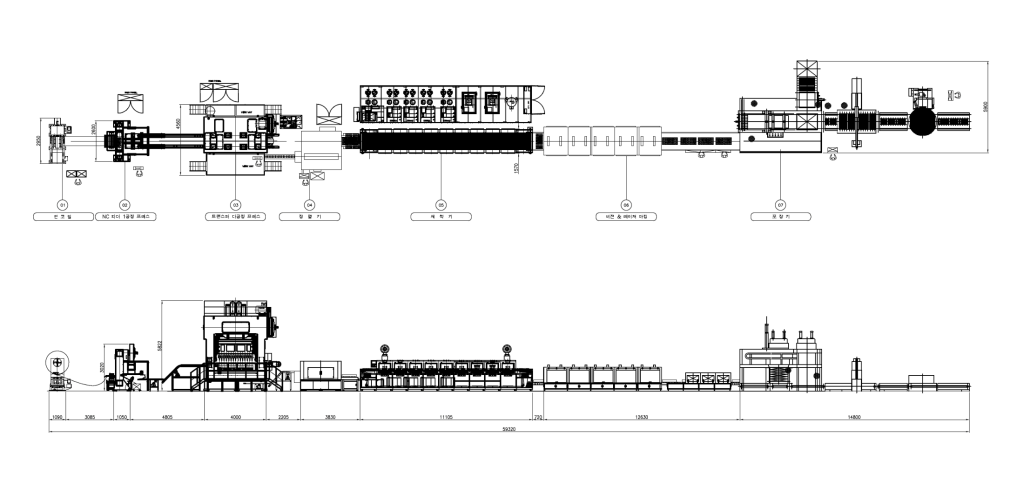

LAYOUT

SPECIFICATIONS

| 1ST CYLINDRICAL CELL CASE PRESS | |

|---|---|

| PRESS CAPACITY | 60~200 T |

| DIE HEIGHT | 390 MM |

| DIE HEIGHT ADJUST | ±30 MM |

| SLIDE STROKE LENGTH | 120 MM |

| TABLE HEIGHT FROM FL | 900 MM |

| NUMBER OF STATIONS | 2ND |

| STROKE PER MIN | 60 SPM |

| ELECTRICAL SOURCE | 380 / 220V 3Ø |

| MAIN MOTOR | 11KW X 6P, 1200 RPM |

| OIL PUMP MOTOR | AC 400W 4P |

| COMPRESSED AIR | 6 KG / cm2 |

| LUBRICANT VOLUME | 6.5L / MIN |

| OIL TANK VOLUME | 100 LITER |

| FLOOR SPACE | W2600 X D1050 |

| HEIGHT OVER ALL | 3030 MM |

| GROSS WEIGHT | APPROX. 15000 KG |

| 2ND CYLINDRICAL CELL CASE PRESS | |

|---|---|

| PRESS CAPACITY | 200~250T |

| DIE HEIGHT | 760 MM |

| SLIDE STROKE LENGTH | 250 MM |

| TABLE HEIGHT FROM FL | 1600 MM |

| NUMBER OF STATIONS | 12ST~14ST |

| TRANSFER STROKE | 160MM |

| STROKE PER MIN | 5~50 SPM |

| ELECTRICAL SOURCE | 380 / 220V 3Ø |

| MAIN MOTOR | 55KW X 6P, 1200 RPM |

| OIL PUMP MOTOR | AC 400W 4P |

| COMPRESSED AIR | 6 KG / cm2 |

| LUBRICANT VOLUME | 30.5L / MIN |

| OIL TANK VOLUME | 280 LITER |

| FLOOR SPACE | W4000 X D2500 |

| HEIGHT OVER ALL | 5730 MM |

| GROSS WEIGHT | APPROX. 70000 KG |

FEATURES

• COMPETITIVE PRICE AND GOOD QUALITY

• VARIOUS SIZES

• DOUBLE DIE SET MOLD

• SPECIAL FACE CAM : MINIMIZE SHAKING OF CARRIER FINGER.

• TOUCH SCREEN : EASILY CHECK MACHINE RUNNING CONDITION AND PROBLEMS

• TRANSPARENT OIL DISTRIBUTOR SYSTEM : EASY TO CHECK OIL RUNNING AND SHORT OF OIL.

• HIGH TECH FINGER SENSOR : MACHINE WILL STOP WHEN PRODUCT DOES NOT RUN SMOOTHLY

• HIGH RIGID FRAME : RATIONALLY DESIGNED FRAME KEEPS SUFFICIENT STRENGTH AND MAINTAINS ACCURATE PRECISION FOR DYNAMIC LOAD.

• ANGLE SEQUENSER CONTROL : PRECISE CONTROL INFORMATION IN RUNNING AND OPERATING WHICH IS SIMPLY PROGRAMMABLE ENABLES TO STOP AT THE TOP DEAD POINT AUTOMATICALLY IN ANY SPEED.

• INVERTOR IS AVAILABLE FOR VARIABLE RUNNING SPEED

• SAFETY : PUTTING THE TRANSPARENT WINDOW IN FRONT OF DIE SET MOLD, EASILY CHECK THE PROBLEM AND WORKER CAN STAY AWAY FROM SAFETY ACCIDENT.

• PLC CONTROL