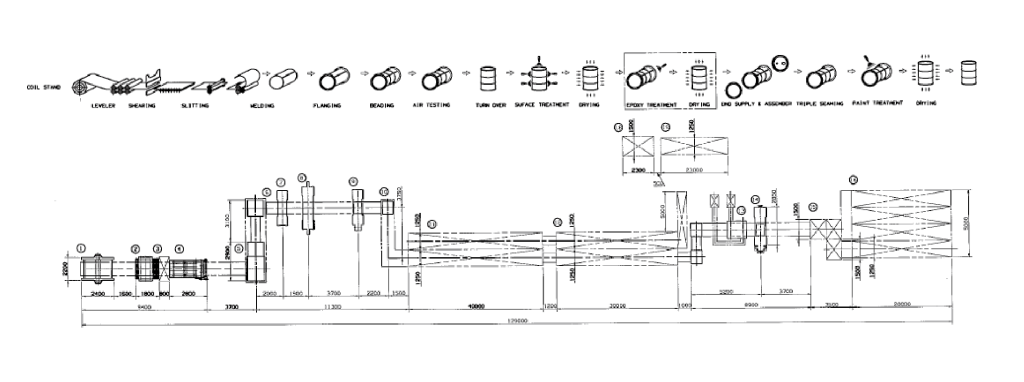

LAYOUT

SPECIFICATIONS

| 1. UNCOILER & NC LEVEL FEEDER | |

|---|---|

| (1) UNCOILER | |

| COIL O.D MAX | MAX.1500 MM |

| COIL I.D MAX | MAX.580 MM |

| COIL WEIGHT MAX. | MAX.7 TON |

| COIL WIDTH MAX. | 1300 MM |

| COIL THICKNESS MAX. | 2.0 MM |

| HEIGHT OVER ALL | 1100 MM |

| MANDREL EXPANSION | AIR |

| (2) LEVELER & NC FEEDER | |

| THICKNESS MAX. | 2.0 MM |

| COIL WIDTH MAX. | MAX.1300 MM |

| WORK ROLL NUMBER | 3*4 |

| FEED ROLL NUMBER | 1 SET |

| HORSE POWER REQUIRED | 3.5 KW/3P/AC SERVO |

| 2. AUTO SHEARING M/C | |

|---|---|

| SHEARING THICKNESSS | MAX. T = 1.6 |

| SHEARING WIDTH | MAX. 1350 MM |

| STROKE PER MIN | 50 S.P.M. |

| HORSE POWER REQUIRED | 2.2 KW |

| FLOOR SPACE | W 2000 X L 800 MM |

| HEIGHT SPACE | 2200 MM |

| NET WEIGHT | 1700 KG |

| WITH SIDE GUIDE & LENGTH GAUGE | |

| 3. AUTO SEAM WELDER |

|---|

| 4. INDEX FEEDING UNIT CONVEYOR | |

|---|---|

| SYSTEM | INDEX CAM UNIT & |

| FEEDING ATTACHMENT | HP 2080 CHAIN & ROLL |

| DRUM DIA | MAX. 600 MM |

| DRUM HEIGHT | MAX. 950 MM |

| FEEDING SPEED | 700 DRUMS/HR |

| HORSE POWER REQUIRED | 3.75 KW |

| FLOOR SPACE | W 1000 X L 7000 MM |

| HEIGHT OVER ALL | 1200 MM |

| 5. AUTO FLANGER | |

|---|---|

| OPERATION SYSTEM | HYDRAULIC SYSTEM |

| FLANGING MOLD | PILOT TYPE |

| SHEET THICKNESS | MAX. T = 1.6 |

| RANGE OF DIA | ψ450 ∼ ψ600 |

| RANGE OF DRUM HEIGHT | MAX. 920 MM |

| CAPACITY | 700 DRUMS/HR MAX. |

| HORSE POWER REQUIRED | 15 KW |

| COMPRESSED AIR | 5 KG/CM² |

| FLOOR SPACE | W 4700 X L 1100 MM |

| HEIGHT OVER ALL | 2200 MM |

| NET WEIGHT | 3800 KG |

| 6. AUTO BEADER | |

|---|---|

| OPERATION SYSTEM | HYDRAULIC SYSTEM |

| SHEET THICKNESS | MAX. T = 1.6 |

| RANGE OF DRUM DIA | ψ450 ∼ ψ600 |

| RANGE OF DRUM HEIGHT | MAX. 920 MM |

| CAPACITY | 700 DRUMS/HR MAX. |

| HORSE POWER REQUIRED | 22.5 KW |

| COMPRESSED AIR | 5 KG/CM² |

| FLOOR SPACE | W 4700 X L 1100 MM |

| HEIGHT OVER ALL | 2200 MM |

| NET WEIGHT | 4700 KG |

| 7. CORRUGATOR | |

|---|---|

| OPERATION SYSTEM | HYDRAULIC SYSTEM |

| SHEET THICKNESS | MAX. T = 1.6 |

| RANGE OF DRUM DIA | ψ450 ∼ ψ600 |

| RANGE OF DRUM HEIGHT | MAX. 920 MM |

| CAPACITY | 700 DRUMS/HR MAX. |

| HORSE POWER REQUIRED | 22.5 KW |

| 8. END ASSEMBLER | |

|---|---|

| ELEVATING MOTOR | 2 POSITION |

| ELEVATING MOTOR | 2.2 KW X 2 |

| END GRIPPING & INSERT UNIT | 2 SETS |

| FLOOR SPACE | W 1800 X L 3500 MM |

| HEIGHT OVER ALL | 2800 MM |

| NET WEIGHT | 2200 KG |

| 9. AUTO TRIPLE SEAMER | |

|---|---|

| OPERATION SYSTEM | HYDRAULIC SYSTEM |

| RANGE OF DRUM DIA | ψ450 ∼ ψ600 |

| END GRIPPING & INSERT UNIT | MAX. 920 MM |

| SHEET THICKNESS | MAX. T = 1.6 |

| CAPACITY | 700 DRUMS/HR MAX. |

| HORSE POWER REQUIRED | 30 KW |

| COMPRESSED AIR | 5 KG/CM² |

| SEAMING ROLL OPERATION | MECJANICAL OPERATION |

| FLOOR SPACE | W 4700 X L 1200 MM |

| HEIGHT OVER ALL | 2400 MM |

| NET WEIGHT | 5600 KG |

| 10. PAINT BOOTH | |

|---|---|

| TYPE | WATER BOOTH |

| AUTO SPRAY RUN | |

| COMPRESSED AIR | 5 KG/CM² |

| FLOOR SPACE | L 3500 X W 4500 MM |

| HEIGHT OVER ALL | 2800 MM |

| NET WEIGHT | 6400 KG |

| 11. DRYING OVEN & COOLER SYSTEM | |

|---|---|

| FEEDING SYSTEM | HIGH PITCH CHAIN(4 LANE) |

| FUEL | LPG |

| DRYING METHOD | SIROCCO |

| HORSE POWER REQUIRED | 15 KW |

| CAPACITY | 300 DR/HR MAX. |

| FLOOR SPACE | W 2700 X L40000 MM |

| HEIGHT OVER ALL | 3800 MM |

| NET WEIGHT | 9200 KG |

FEATURES

• CAPACITY : 400~720 DRUMS/HOUR

• PLC CONTROL

• CENTRAL LUBRICANT OIL SYSTEM

• HIGH RIGID FRAME : RATIONALLY DESIGNED FRAME KEEPS SUFFICIENT STRENGTH AND MAINTAINS ACCURATE PRECISION FOR DYNAMIC LOAD.

• INVERTOR IS AVAILABLE FOR VARIABLE RUNNING SPEED.

• WORLD STANDARD DRUM SIZE AND CUSTOMIZED DRUM DESIGN.

• ISO 9001:2000 CERTIFIED PRODUCT.