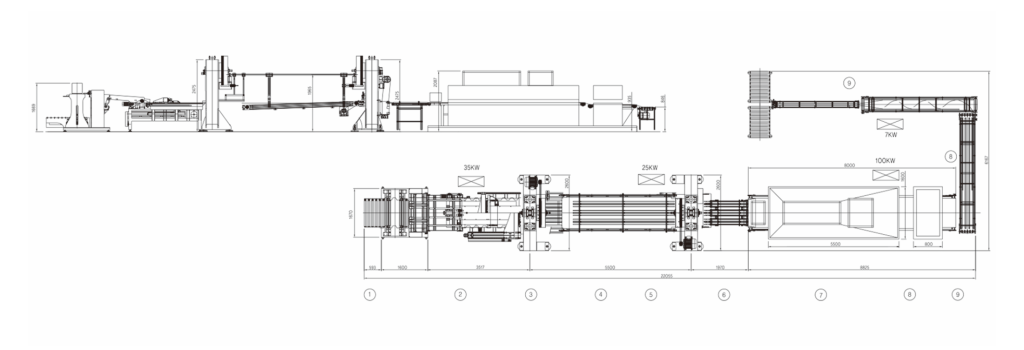

LAYOUT

SPECIFICATIONS

| (1) AUTO SHEET FEEDER | |

|---|---|

| CAPACITY | MAX.25SHEETS/MIN |

| SHEE THICKNESS | MAX. T=0.4 |

| MAX.SHEET SIZE | 1060 x 1060 MM |

| MAX.LOADING WEIGHT | 2 TON |

| HORSE POWER REQUIRED | 3.75 KW |

| VACUUM PUMP | 1.5kw. 600L/MIN |

| AIR CONSUMPION | 40L / MIN |

| MACHINERY WEIGHT | 1500 KG |

| FLOOR SPACE | 1670 x 2000MM |

| HEIGHT OVER ALL | 1669 MM |

| (2) SHEET TRANSFER M/C | |

|---|---|

| MAX.SHEET SIZE | 1060 x 1060 MM |

| SERVO | 3Kw(1ea)2kw(1ea)0.7kw(1ea) |

| DOUBLE SHEET DETACTOR | 1 SET |

| AIR CONSUMPTION | 12L / MIN |

| HORES POWER REQURED | 5.62KW |

| FLOOR SPACE | 1700 x 3200 MM |

| HEIGHT OVER ALL | 1170 MM |

| (3) SHEET TRANSFER M/C | |

|---|---|

| PRESS CAPACITY | 30Tf |

| STROKE PER MIN | 110spm |

| DIE HEIGHT | 360 MM |

| OPEN HEIGHT | 480 MM |

| SLIDE STROKE LENGTH | 130 MM |

| DIE HEIGHT ADJUST | ±10mm |

| SLIDE AREA | 900*200 MM |

| BED AREA | 900*200 MM |

| TABLE HEIGHT from FL | 830 MM |

| MAIN MOTOR | 7.5Kw x 6p,1150rpm |

| COMPRESSED AIR | 5Kg/cm |

| AIR CONSUMPTION | 350 L/MIN |

| OIL TANK VOLUME | 50Liter |

| FLOOR SPACE | W 2600 x D 1140 |

| HEIGHT OVER ALL | 2600MM |

| ROSS WEIGHT | Approx.8000Kg |

| (4) ACCUMULATION CNVEYOR | |

|---|---|

| PRESS POWER REQUIRED | 1.5KW |

| BELT | PLASTIC TOP CHAIN |

| (5) TRANSFER PRESS & LINER | |

|---|---|

| PRESS CAPACITY | 30Tf |

| STROKE PER MIN | 110spm |

| DIE HEIGHT | 360 MM |

| OPEN HEIGHT | 400MM |

| SLIDE STROKE LENGTH | 480 MM |

| DIE HEIGHT ADJUST | 130 MM |

| SLIDE AREA | ±10 MM |

| BED AREA | 900*200 MM |

| NUMBER of STATIONS | 900*200 MM |

| TABLE HEIGHT from FL | (3+1) x 6 set |

| MAIN MOTOR | 1000 MM |

| COMPRESSED AIR | 7.5Kw x 6p,1150rpm |

| AIR CONSUMPTION | 5Kg/cm |

| OIL TANK VOLUME | 50Liter |

| FLOOR SPACE | W 2600 x D 1140 |

| HEIGHT OVER ALL | 2600MM |

| GROSS WIEHGT | Approx.8000Kg |

| (6) CONVERYOR | |

|---|---|

| HORSE POWER REQUIRED | 0.75KW |

| (7) DRYER | |

|---|---|

| MAIN CONVEYOR MOTOR | 2.2KW |

| ELECTRONIC HEART | 76KW + 6KW |

| FAN MOTOR | 0.4KW x 6SET |

| COOLING FAN MOTOR | 0.4KW x 6set |

| CHAIN,MESH BELT | SUS304 |

| FLOOR SPACE & HEIGHT | 8000 x 1600 x 2000MM |

| (8) CONVEYOR | |

|---|---|

| HORSE POWER REQUIRED | 0.75KW |

| BELT | PLASTIC TOP CHAIN |

| (9) PACKING | |

|---|---|

| HORSE POWER REQUIRED | 0.75 KW x 2 |

| CONVEYOR 2 SET | 2 SET |

| DELIVERY CONVEYOR | ROLLER TYPE |

| DIVIDER | 1 SET |

| COUNT | 1 SET |

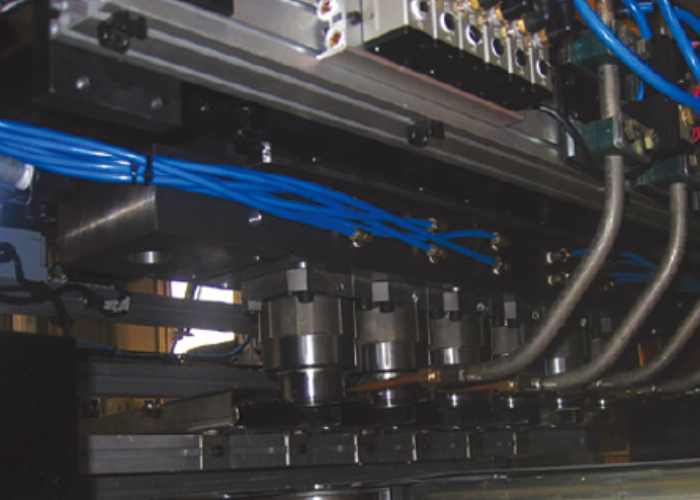

FEATURES

• COMPETITIVE PRICE AND GOOD QUALITY

• VARIOUS SIZE WITH EASY CHANGEABLE DIE SET MOLD.

• MULTI DIE SET MOLD

• ZIGZAG & STRAIGHT FEEDING SYSTEM

• TOUCH SCREEN : EASILY CHECK MACHINE RUNNING CONDITION AND PROBLEMS.

• TRANSPARENT OIL DISTRIBUTOR SYSTEM : EASY TO CHECK OIL RUNNING AND SHORT OF OIL.

• HIGH TECH SENSOR : MACHINE WILL STOP WHEN PRODUCT DOES NOT RUN SMOOTHLY.

• HIGH RIGID FRAME : RATIONALLY DESIGNED FRAME KEEPS SUFFICIENT STRENGTH AND MAINTAINS ACCURATE PRECISION FOR DYNAMIC LOAD.

• ANGLE SEQUENCER CONTROL : PRECISE CONTROL INFORMATION IN RUNNING AND OPERATING WHICH IS SIMPLY PROGRAMMABLE ENABLES TO STOP AT THE TOP DEAD POINT AUTOMATICALLY IN ANY SPEED.

• INVERTOR IS AVAILABLE FOR VARIABLE RUNNING SPEED

• SAFETY : PUTTING THE TRANSPARENT WINDOW IN FRONT OF DIE SET MOLD, EASILY CHECK THE PROBLEM AND WORKER CAN STAY AWAY FROM SAFETY ACCIDENT.

• PLC CONTROL.