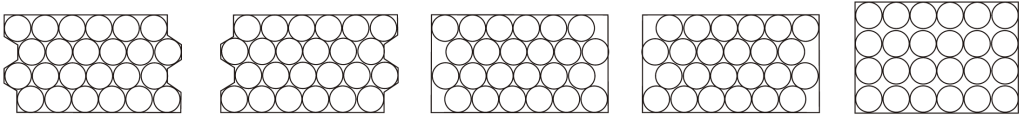

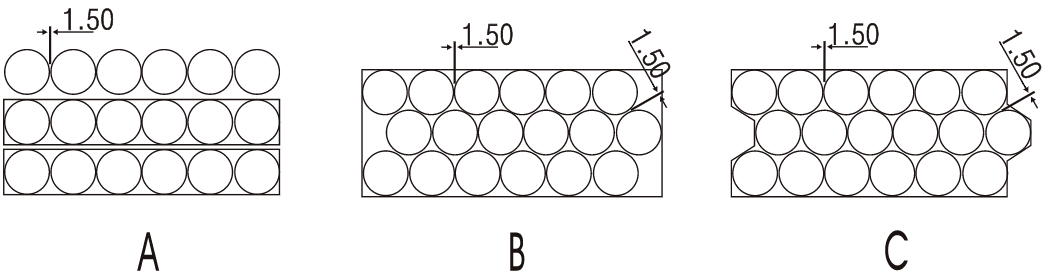

LAYOUT

SHEET PATTERNS

MATERIAL UTILIZATION COMPARISION

• End Size : 211D. cut edge Ø85.50mm 12column. 11 Row. 132/Ends/Sheet

• Compare with A type sheet. C type sheet will be able to save 14.6% material.

| TYPE | UTILIZABLE AREA (cm2) |

SHEET AREA (cm2) |

UTILIZABLE (%) |

|---|---|---|---|

| A | 7574.88 cm2 | 10592.79 cm2 | 71.5 % |

| B | 7574.88 cm2 | 9156.75 cm2 | 82.7 % |

| C | 7574.88 cm2 | 8790.50 cm2 | 86.1 % |

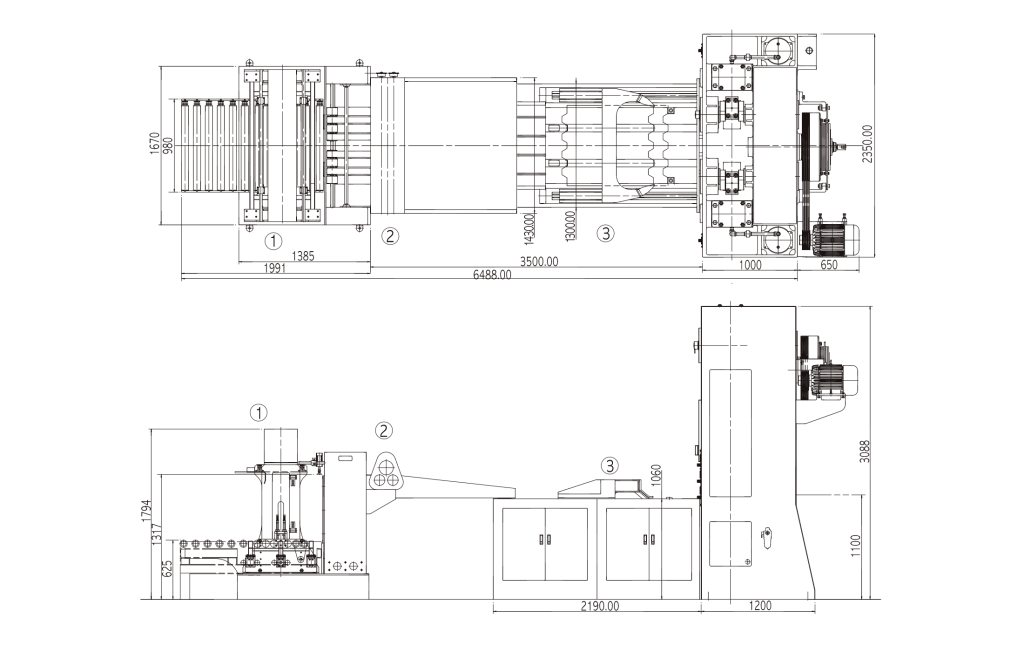

SPECIFICATIONS

| (1) AUTO SHEET FEEDER | |

|---|---|

| MAX. SHEET SIZE | 1060x1060MM |

| CAPACITY PER MIN | MAX. 25-30 SHEETS/MIN |

| MAX. LOADING WEIGHT | 3 TON |

| HORES POWER | 3.75 KW BRAKED MOTOR |

| VACUUM PUMP | 600L/MIN.2HPx4P |

| MACHINERY WEIGHT | 1500KG |

| DOUBLE SHEET DETACTOR | 1SET |

| SEPARATING MAGNET | 2EA |

| FLOOR SPACE | 1385×1670 MM |

| HEIGHT OVER ALL | 1794MM |

| SHEET THICKNESS | MAX. T = 0.4 |

| MAX. SHEET SIZE | 1060x1060MM |

| (2) SHEET TRANSFER M/C | |

|---|---|

| TOTAL STROKE | 1060x1060MM |

| TRANSFER PICH | 87.00MM |

| ELECTRICA SOURCE | 220V3ф |

| HORSE POWER REQUIRED | 9KW |

| SEVO&BALL SCREW SYSTEM | – |

| FLOOR SPACE | 2000x1300MM |

| HEIGHT OVER ALL | 1060MM |

| (3) OILLER | |

|---|---|

| FLAME SIZE(WxLxH) | 1430x400x360MM |

| (4) CNC SHEET FEEDER PRESS | |

|---|---|

| MODEL | CSFP 80-211 x 11 |

| POWER | 80TF |

| STROKE LENGTH | 140MM |

| DIE HEIGHT | 400MM |

| S.P.M | MAX. 100SPM |

| TABLE SIZE | 1400 x 600MM |

| 211 DOME x 11CUT | – |

| MAX.SHEET SIZE | 1060 x 1060 MM |

| MOULD NUMBER | 11 SET |

| ELECTRICA SOURCE | 220V3ф |

| HORSE POWER REQUIRED | 20HP |

| FLOOR SPACE | 2350 x 1200MM |

| HEIGHT OVER ALL | 3088MM |

FEATURES

• COMPETITIVE PRICE AND GOOD QUALITY

• VARIOUS SIZES : SIZES ARE BETWEEN 200D AND 211D WITH EASY CHANGEABLE DIE SET MOLD.

• DOUBLE DIE SET MOLD : MAXIMIZE PRODUCTIVITY WITH 200 LIDS PER MIN. • SPECIAL FACE CAM : MINIMIZE SHAKING OF CARRIER FINGER.

• TOUCH SCREEN : EASILY CHECK MACHINE RUNNING CONDITION AND PROBLEMS

• TRANSPARENT OIL DISTRIBUTOR SYSTEM : EASY TO CHECK OIL RUNNING AND SHORT OF OIL.

• HIGH TECH FINGER SENSOR : MACHINE WILL STOP WHEN PRODUCT DOES NOT RUN SMOOTHLY

• HIGH RIGID FRAME : RATIONALLY DESIGNED FRAME KEEPS SUFFICIENT STRENGTH AND MAINTAINS ACCURATE PRECISION FOR DYNAMIC LOAD.

• ANGLE SEQUENSER CONTROL : PRECISE CONTROL INFORMATION IN RUNNING AND OPERATING WHICH IS SIMPLY PROGRAMMABLE ENABLES TO STOP AT THE TOP DEAD POINT AUTOMATICALLY IN ANY SPEED.

• INVERTOR IS AVAILABLE FOR VARIABLE RUNNING SPEED

• SAFETY : PUTTING THE TRANSPARENT WINDOW IN FRONT OF DIE SET MOLD, EASILY CHECK THE PROBLEM AND WORKER CAN STAY AWAY FROM SAFETY ACCIDENT.

• PLC CONTROL