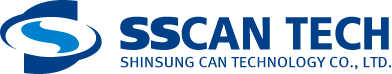

LAYOUT

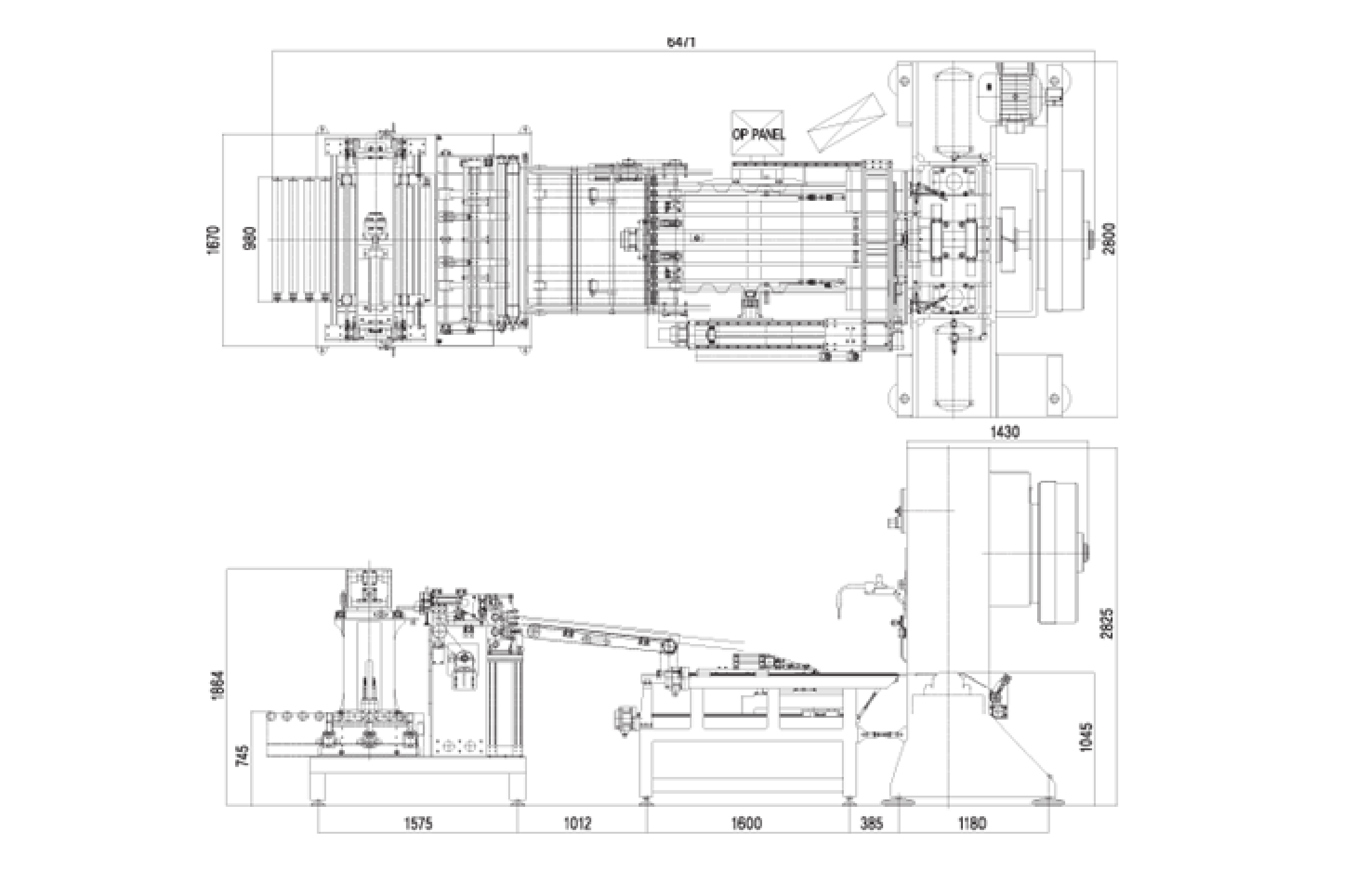

SHEET PATTERNS

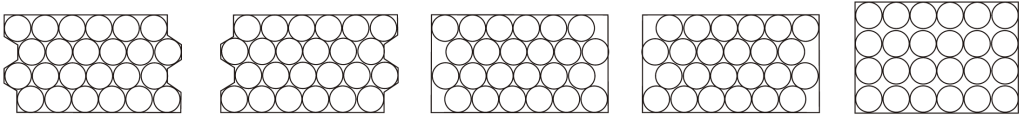

MATERIAL UTILIZATION COMPARISION

• End Size : 211D. cut edge Ø85.50mm 12column. 11 Row. 132/Ends/Sheet

• Compare with A type sheet. C type sheet will be able to save 14.6% material.

| TYPE | UTILIZABLE AREA (cm2) |

SHEET AREA (cm2) |

UTILIZABLE (%) |

|---|---|---|---|

| A | 7574.88 cm2 | 10592.79 cm2 | 71.5 % |

| B | 7574.88 cm2 | 9156.75 cm2 | 82.7 % |

| C | 7574.88 cm2 | 8790.50 cm2 | 86.1 % |

SPECIFICATIONS

| PRESS CAPACITY | 30TON | 60TON | 80TF | 110TF |

|---|---|---|---|---|

| Stroke Per Min | 110 spm | 110 spm | 80 spm | 110 spm |

| Die Hight | 360mm | 390mm | 400mm | 380mm |

| Open Hight | 480mm | 510mm | 460mm | 520mm |

| Slide Strok Lanth | 130mm | 140mm | 600mm | 140mm |

| Die Hight | 10mm | 20mm | 20mm | 35mm |

| Slide Area | 900 x 200mm | 900 x 250mm | 1500 x 300mm | 960 x 450mm |

| Ded Area | 900 x 200mm | 1200 x420mm | 1600 x 400mm | 1200 x 560mm |

| Main Motor | 7.5kw x 6p,1150rpm | 11kw x 6p,1150rpm | 18.5kw x 4p | 22kw x 4p |

| Slider Adjust Motor | Hand Type | 0.75kw x 4p | 0.75kw x 4p | 0.75 x 4p |

| Compressed Air | 10kg/cm | 10kg/cm | 10kg/cm | 10kg/cm |

| Air Consumption | 350 /min | 350 /min | 350 /min | 350 /min |

| Oil Tank Volume | 50 | 80 | 100 | 270 |

| Fllor Space | W2600 x D1140 | W2600 x D1190 | W2600 x D1240 | W2350 x D1200 |

| Hight Over All | 2600mm | 2700mm | 2800mm | 2825mm |

| Gross Weight | Approx 8000kg | Approx 10000kg | Approx 12000kg | Approx 14000kg |

FEATURES

• COMPETITIVE PRICE AND GOOD QUALITY

• VARIOUS SIZES : SIZES ARE BETWEEN 200D AND 211D WITH EASY CHANGEABLE DIE SET MOLD.

• DOUBLE DIE SET MOLD : MAXIMIZE PRODUCTIVITY WITH 200 LIDS PER MIN.

• SPECIAL FACE CAM : MINIMIZE SHAKING OF CARRIER FINGER.

• TOUCH SCREEN : EASILY CHECK MACHINE RUNNING CONDITION AND PROBLEMS

• TRANSPARENT OIL DISTRIBUTOR SYSTEM : EASY TO CHECK OIL RUNNING AND SHORT OF OIL.

• HIGH TECH FINGER SENSOR : MACHINE WILL STOP WHEN PRODUCT DOES NOT RUN SMOOTHLY

• HIGH RIGID FRAME : RATIONALLY DESIGNED FRAME KEEPS SUFFICIENT STRENGTH AND MAINTAINS ACCURATE PRECISION FOR DYNAMIC LOAD.

• ANGLE SEQUENSER CONTROL : PRECISE CONTROL INFORMATION IN RUNNING AND OPERATING WHICH IS SIMPLY PROGRAMMABLE ENABLES TO STOP AT THE TOP DEAD POINT AUTOMATICALLY IN ANY SPEED.

• INVERTOR IS AVAILABLE FOR VARIABLE RUNNING SPEED

• SAFETY : PUTTING THE TRANSPARENT WINDOW IN FRONT OF DIE SET MOLD, EASILY CHECK THE PROBLEM AND WORKER CAN STAY AWAY FROM SAFETY ACCIDENT.

• PLC CONTROL